perseverance | when good just isn't good enough

Recording the amount of time that goes into a build can be a good way of gauging how much work has been invested. Strictly going by billable hours isn’t exactly what we mean, however, because more than likely, you’d be building your way right into the poorhouse in a matter of months with a truck like the one featured here. For people who are able to do their own work, or can trade labor with others, the time invested in a build means much more than an hourly rate. Hours can turn into days in the blink of an eye, but just so everyone’s on the same page, we’ll stick to 60-minute units of measurement.

Roughly 3,000 hours during the course of three years were sunk into Jeff “Speedy” Baumann’s ‘67 C-10. That’s 125 solid days of round-the-clock progress. One thousand six hundred plus additional hours (on top of the 3,000) were invested inside the cab alone. We could break down this entire build into some migraine-inducing calculus equation to get more insight into the process, or we can take a more personable approach and meet the man behind this nearly flawless Chevy specimen instead.

“He’s been through the VW Bug stage and into the mini-truck era, and he has since turned his love of customizing vehicles into his profession.”

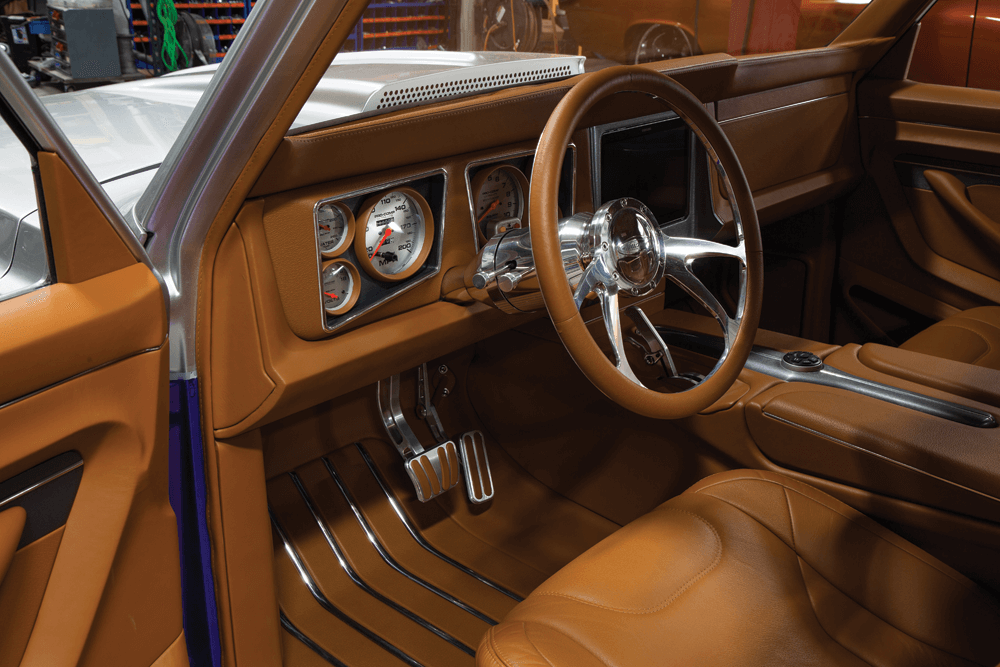

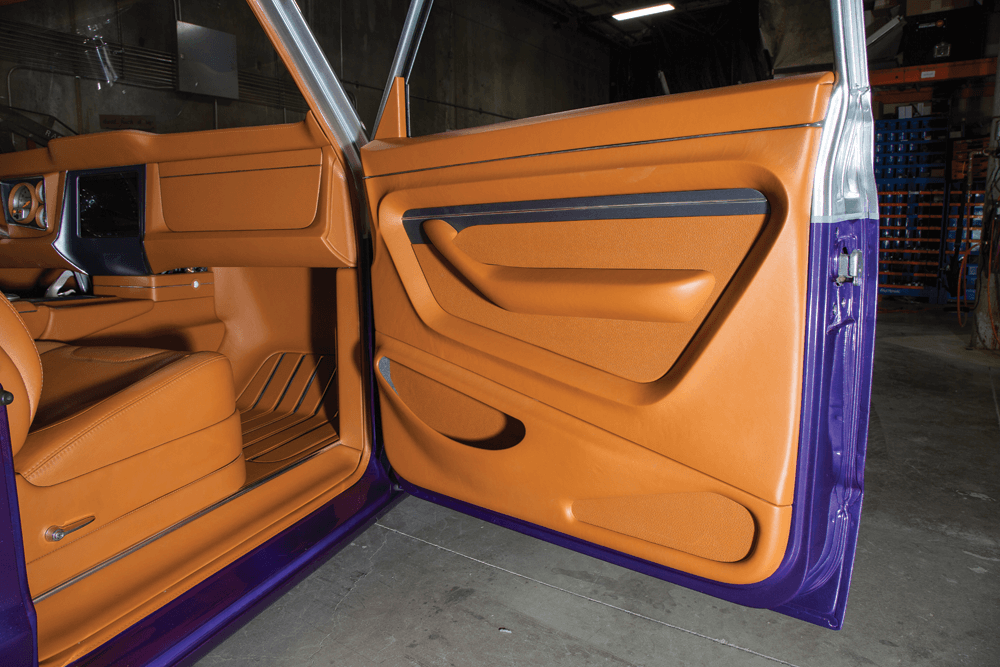

Every inch of the interior has been given the full custom treatment.

The full-custom bucket seats designed and created by HRH Designs are simply gorgeous. Who would even think about leaving this space?

Jeff has been into custom cars and trucks since he was in high school—so, more than 20 years. He’s been through the VW Bug stage and into the mini-truck era, and he has since turned his love of customizing vehicles into his profession. He has assumed the pressure that comes with transforming other people’s personal projects into showpieces that travel the country to events. He’s always been into customization, but in the last few years Jeff has aimed to share the spotlight that shines on builders he’s looked up to throughout his years of study. “Building cars and trucks that have done well at shows and that have been featured in magazines is rewarding, but the time to create something new just for me finally presented itself,” Jeff says.

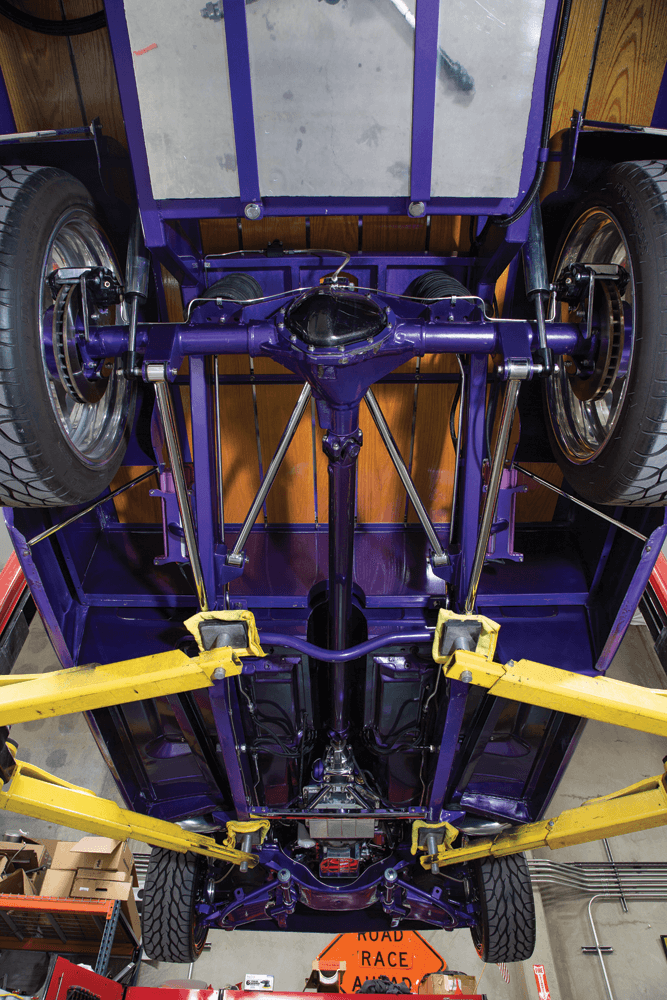

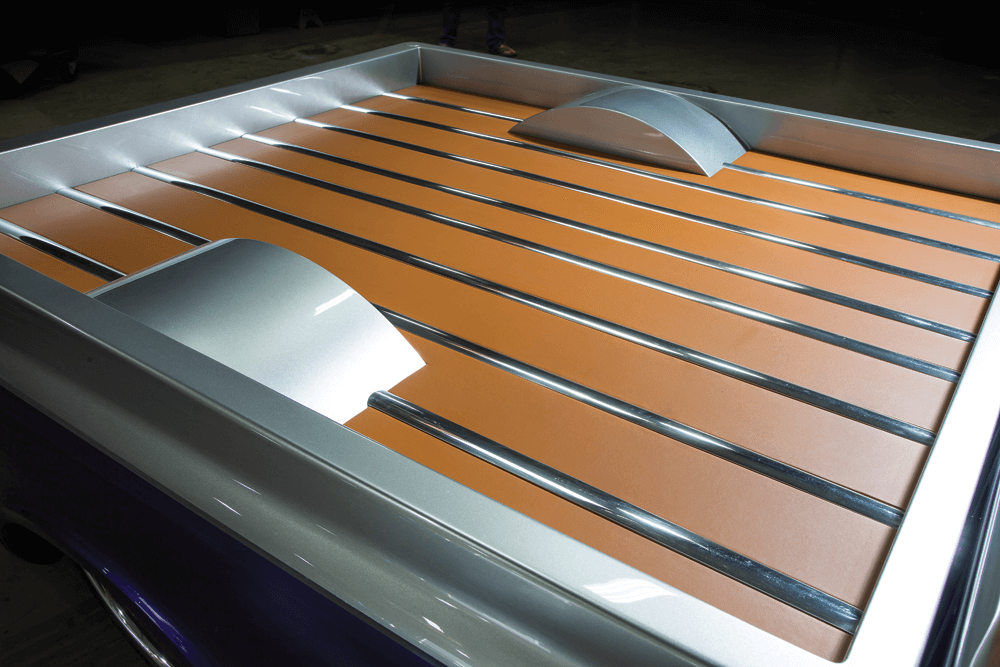

A custom bed floor keeps the rear looking classy while giving the rear suspension system enough breathing room to do its thing.

One look at a chassis like this is all it takes to confirm that the rest of the build is going to feature equal parts craftsmanship and style.

A Samsung tablet sits center stage in the dash for the ultimate audio-visual experience.

This C-10 here was a birthday gift from his wife. “It was in pretty rough shape,” Jeff admits. “It was a farm truck from Idaho and had lots of normal rust spots in the floor, rockers, drip rails, etc., but I knew exactly what was needed to get it into show-winning condition.” At this point, Jeff was just about to make a transition to become a full-time employee at Nostalgia Hot Rods (NHR) of Las Vegas. He was previously working at another shop across town, but things quickly changed after he met NHR’s owner and operator, Dustin “Bud” Hacker.

“I met Dustin about six years prior at another body shop I was working at. He would come into the shop with different hot rods and all sorts of custom cars and trucks he was working on for his customers. He had just started Nostalgia Hot Rods, and it seemed like he was taking on and handling a lot of jobs on his own. I went over to his shop to see if he needed any help to get up and going, and I’ve been Dustin’s right hand ever since.”

Of course, the more vehicles out there stamped with the NHR seal of approval, the better for the brand name. Jeff’s C-10 was already in the works when he met Dustin, and since he acknowledged that it was headed in the right direction, the guys proceeded to make the truck an official shop build. It was at the NHR compound where the Chevy really started taking shape. Jeff and Dustin were able to collaborate and bounce ideas off of each other in real time. Aside from the styling cues the two were cooking up in the shop, Jeff had always looked to his favorite builders for inspiration. “I’ve always been a fan of guys like Chip Foose, Troy Trepanier and Dave Kindig. I try to look at their projects that I like and ask myself how I could do things better or different to suit my personal preferences.”

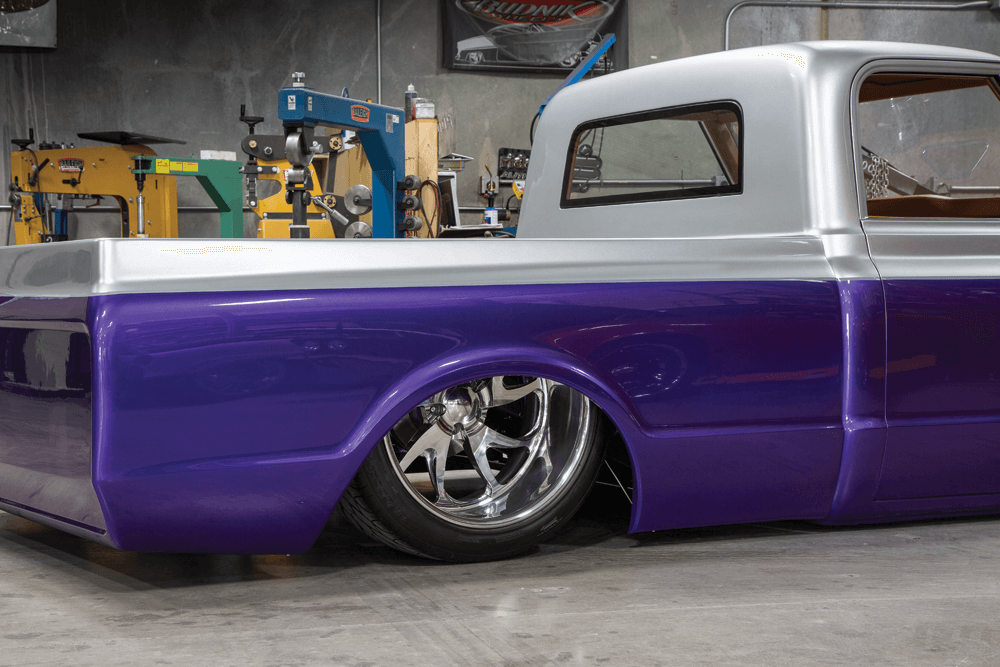

Jeff and Dustin ended up with a plan for an asphalt-hugging suspension system featuring a custom frame that would soon be decked out with top-end accessories from CPP, RideTech, Firestone and Wilwood, just to name a few. With a solid foundation to build upon, the C-10 would then be ready to receive the magic needed to turn the old rust bucket into a regular shining star.

Jeff had begun the process of ridding the body of any unnecessary parts or contours that didn’t play along with the exact image he had in mind. The cowl induction hood, smoothed front bumper and entire rearend play a pivotal role in forming the streamlined silhouette Jeff had envisioned for a long time. Details like the flush-mounted front and rear glass also give the truck a certain look that a great deal of onlookers might not be able to call out specifically, although even the casual observer recognizes that something different is going on with the truck’s unique styling.

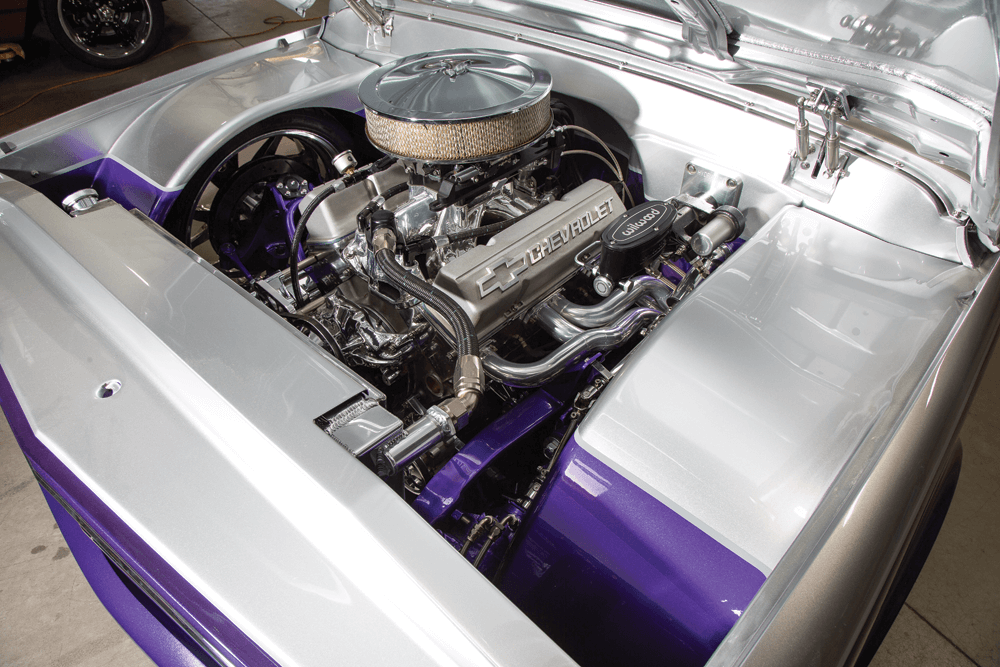

Considering those items, along with a custom raised bed floor and time spent in paint (including the coated chassis), there are a whole bunch of work hours invested under the hood. The inner fenders, firewall and detail work that went into creating such a clean engine compartment—not even taking into account the complete build of the decked out small-block—is pretty staggering. It begins to make sense when you consider where those 3,000 hours we mentioned earlier were spent. The crazy part comes when you remember the additional 1,600 hours represented in the cab alone. HRH Designs created custom bucket seats, mapped out a custom dashboard, and then totally jumped into the deep end. Imported Scottish leather seems to have taken over the entire cab. It wraps the custom center console, door panels, dash and the cushy seats. The material selection and craftsmanship are definitely on par with any luxury vehicle known. The interior space really helps place Jeff’s truck on a higher pedestal than most. It really is that special.

In three years’ time, Jeff and the NHR team called this project complete, and they’ve started planning its victory lap tour this year. Jeff might not have expected the truck to end up at this caliber initially, but ultimately, he’s not surprised that it did. He and Dustin used every available resource (as they do with all NHR builds) to not only get the job done, but to set it apart from all other trucks on the road.

“Now that we’re done with this one, look for it at local Vegas events and on tour at Goodguys shows across the West Coast,” Jeff says. The guys designed this Chevy to be different and invested the time to build it. If given the opportunity to see it up close, you’d be wise to seize the day and take a moment to appreciate something that took so long to produce.

Darren at HRH Designs is responsible for the transformation of the dapper interior, which now features exotic Scottish leather and contrasting accessories from Auto Meter, Budnik and many more.

The SBC has been punched out to a 434 and is sporting a long list of stellar, high-performance accessories. Just check out the metal and paint work—incredible.

“If given the opportunity to see it up close, you’d be wise to seize the day and take a moment to appreciate something that took so long to produce.”